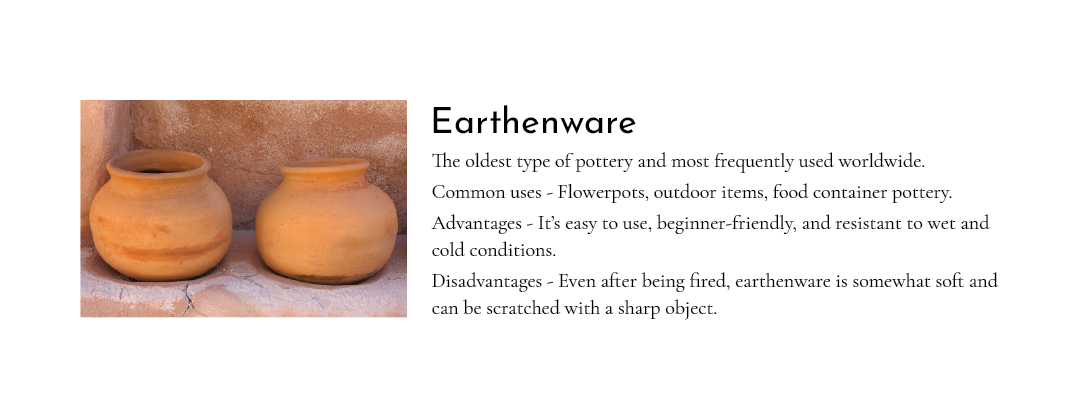

Photo By Isabella Huelsman

Susan Abramovitz with her work.

Rock Riffle Run Pottery

Susan Abramovitz has been a potter for over 50 years. Originally from Youngstown, OH, she has had a long career in ceramics. Abramovitz worked as the head of the ceramics department at Case Western Reserve University for a time, before she decided to start her own business in Athens. Rock Riffle Run Pottery, on Rock Riffle Run Road began in 1978. She was forced to move to Shade, Ohio, when the highway was built.

“It's never boring, and it's also really hard physical work, which is hard to do but really good for you in the long run. And I'm 70 and I'm still working, that's good and bad.”

Abramovitz has made a living in clay ever since. She picked the area “because it was rural, and was near [her] supplies. It was isolated and a really good place to work.”

This proximity to the clay and nature has greatly influenced Abramovitz’s career. The clay industry and mining in Southeast Ohio is extractive, but Abramovitz sees her work as beneficial, and a byproduct of the industry.

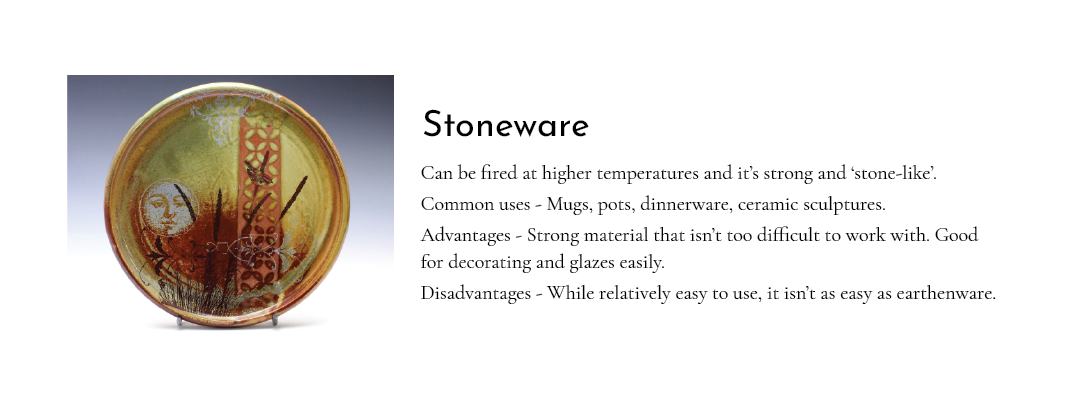

Photo by Isabella Huelsman

Susan Abramovitz throws a mug on the wheel that will later have a company logo stamped on it.

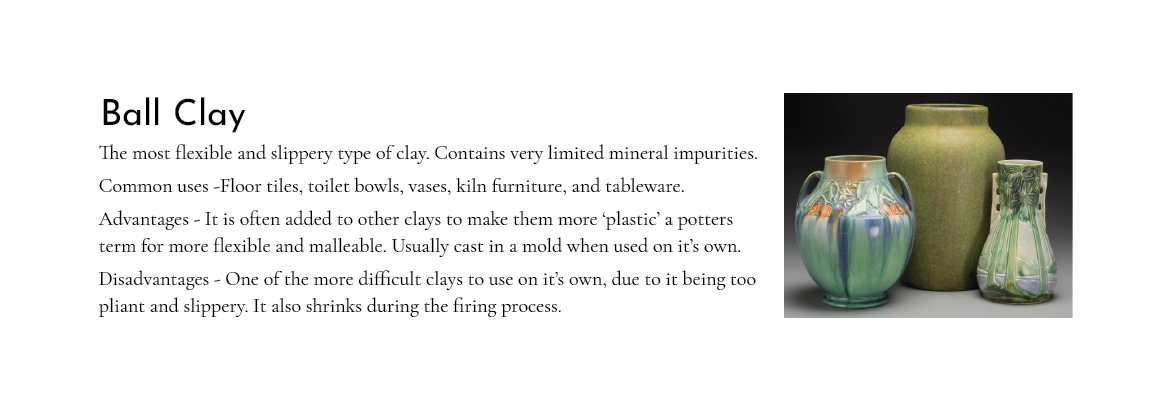

Photo by Isabella Huelsman

Abramovitz makes hundreds of mugs every year. It takes her under five minutes to throw a mug.

Around 1984, she had the opportunity to work directly with Cedar Heights Clay, in Oak Hill, Ohio, in the development of GoldArt, a very popular commercial arts clay. She was able to work as a field tester and make pieces out of the clay to see how it would react in a commercial firing environment. The work allowed her to travel to mining sites, and see the entire process of the clay industry. The clay had a high sulfur content and contaminants, which are not favorable in firing, and through the testing, they were able to eliminate the flaws to produce a clay with a high industry standard.

“It's just you know, it's a question of, that's where it comes from. Somebody's always digging it if they're using it, it's just you know, is it me or the industry?”

Abramovitz still uses Cedar Heights clay in her products today. Her line has 70 to 100 different products, majorly made with these regional clays. She makes mugs, bowls, plates, planters, clocks, garlic keepers, urns, jars, and a variety of other products.

Her favorite part of the process is throwing on the wheel, but it’s hard to compete with unloading a kiln full of glazed and finished pots. The reward of the long ceramic process is seeing the finished pieces, and Abramovitz is motivated by her successes.

“If you throw 100 things and you get one right, and you can feel it, you go, I gotta do that again! So you just keep going.”

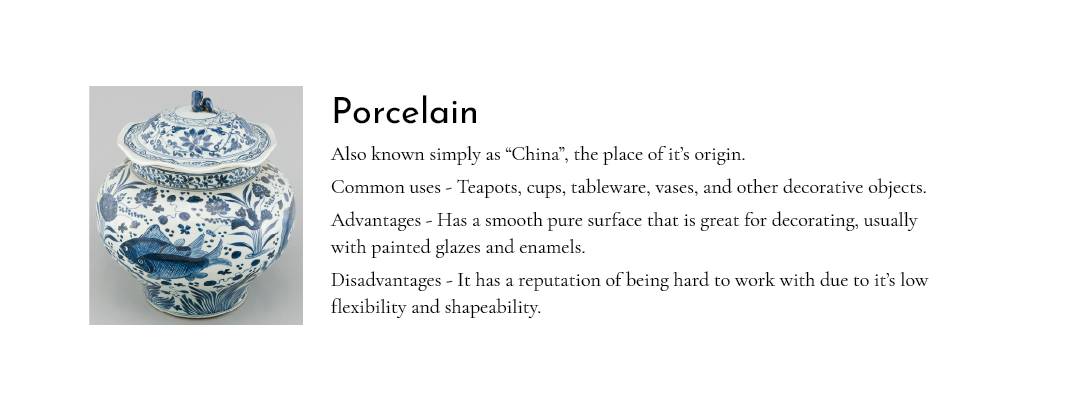

Photo By Isabella Huelsman

Finished mugs for sale sit in the sun in Abramovitz’s showroom.