Photo by Avery Waffen

Aerial view of Crownover Lumber facilities and lumber yard. McArthur, Ohio, April 1, 2022

Sustainable Logging at Crownover Lumber

Story by Avery Waffen

Crownover Lumber is located in McArthur Ohio near Lake Hope. It has been operating since 1954 and has seen many owners and many advances since its opening.

Photo by Avery Waffen

Logs being unloaded onto the lumber yard by a forklift outfitted for logging. McArthur, Ohio.

Photo by Avery Waffen

Trucks carrying logs from the surrounding woods arrive at Crownover. Around 20 of these trucks come by each day to drop off wood. McArthur, Ohio.

Crownover Lumber orchestrates the chopping and shipping of the trees to their facility, and they are sure to bring trees down carefully so as not to harm saplings– which are the future of their business. They buy most of their logs from private landowners who either want the trees gone or want to make a profit while making room for smaller trees to grow. The trees are carefully cut to not damage saplings and are trimmed before being removed from the woods. This is to prevent the scarring of other trees.

Once the logs are brought to the facility, they are unloaded and sorted based on tree type; they deal in hardwoods like Poplar, Cherry, and Oak. The sorted logs are taken to the de-barker, which removes the bark from the logs.

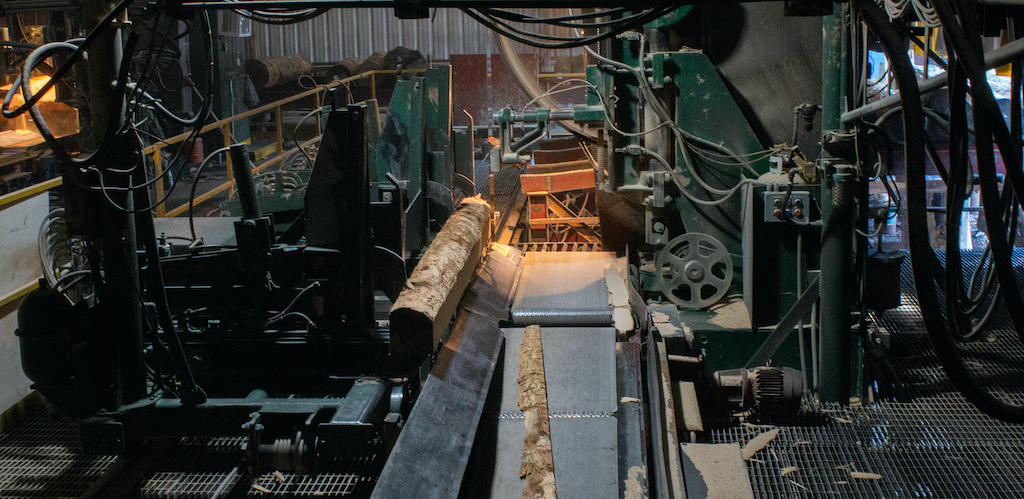

Next, logs go to one of two Sawmills on the property which use a 41-foot-long bandsaw to cut the log into boards. The saw blade must be replaced twice a day to keep it sharp. Dull blades are taken to be leveled and sharpened, as well as any broken pieces welded. Cut into rough boards, the wood is sent down a conveyer belt to be labeled and checked for trimming.

From here, logs are sorted based on size and wood type. The boards are shipped out all over North America. All the bark, cuttings, and scrap wood that has been cut off is turned into sawdust or pellets for wood burning grills. By using every part of the log, Crownover is making more money while creating minimal waste.

I talked with Steve Reed at his office in McArthur, Ohio to learn more about why he cares so much about sustainability and to learn about his rise from line worker to owner of the company | Audio by Avery Waffen

“I live here too.”

I sat down with Steve Reed who worked at Crownover since 1980 and just recently bought the company. He says ‘maintaining his community’ is what is most important to him. Crownover keeps jobs in McArthur and often donates to local charities. Steve says Crownover and the Crownover family has been donating to local charities even before he owned it. Only now, much of the charity work involves the local middle school where Steve’s wife works. “My wife always finds something that needs donations” he says. Steve says this love for the community encourages their sustainable business practices; they harvest all their logs within 30 miles of McArthur. “I live here too” says Steve.

When he bought the company in November 2020, one thing he never expected was the effect it would have on the town. Steve says when he first bought the company, he had locals come up to him in the store and on the street thanking him for keeping jobs in the area because, much like the coal mining jobs that started McArthur, the logging jobs keep the town running.

More about the current industry...

Wayne National Forest

Land Stewardship and Conservation

Over the past century or so, an ambitious undertaking has been ongoing in Athens and surrounding counties: the Wayne National Forest. The only National Forest in Ohio, the Wayne was begun following the United States’ government realization of the extent of the deforestation in the eastern United States. Being an especially devastated, barren area, southern Ohio was targeted for restoration efforts…